粘度

粘度

润滑油最重要的物理性质是粘度。 粘度决定了油液的承载能力以及流动性。 对于任何润滑油的选用,必须在提高承载能力的高粘度和易于循环的低粘度之间取得正确的平衡。 除了润滑之外,油液

在所有条件下都能流动是至关重要的。在使用中,污染物例如水分的混入,进入机油的燃料油,润滑油的氧化和烟炱都影响着润滑油的粘度。因此,粘度测量是机械系统中油液最重要的测试之一。

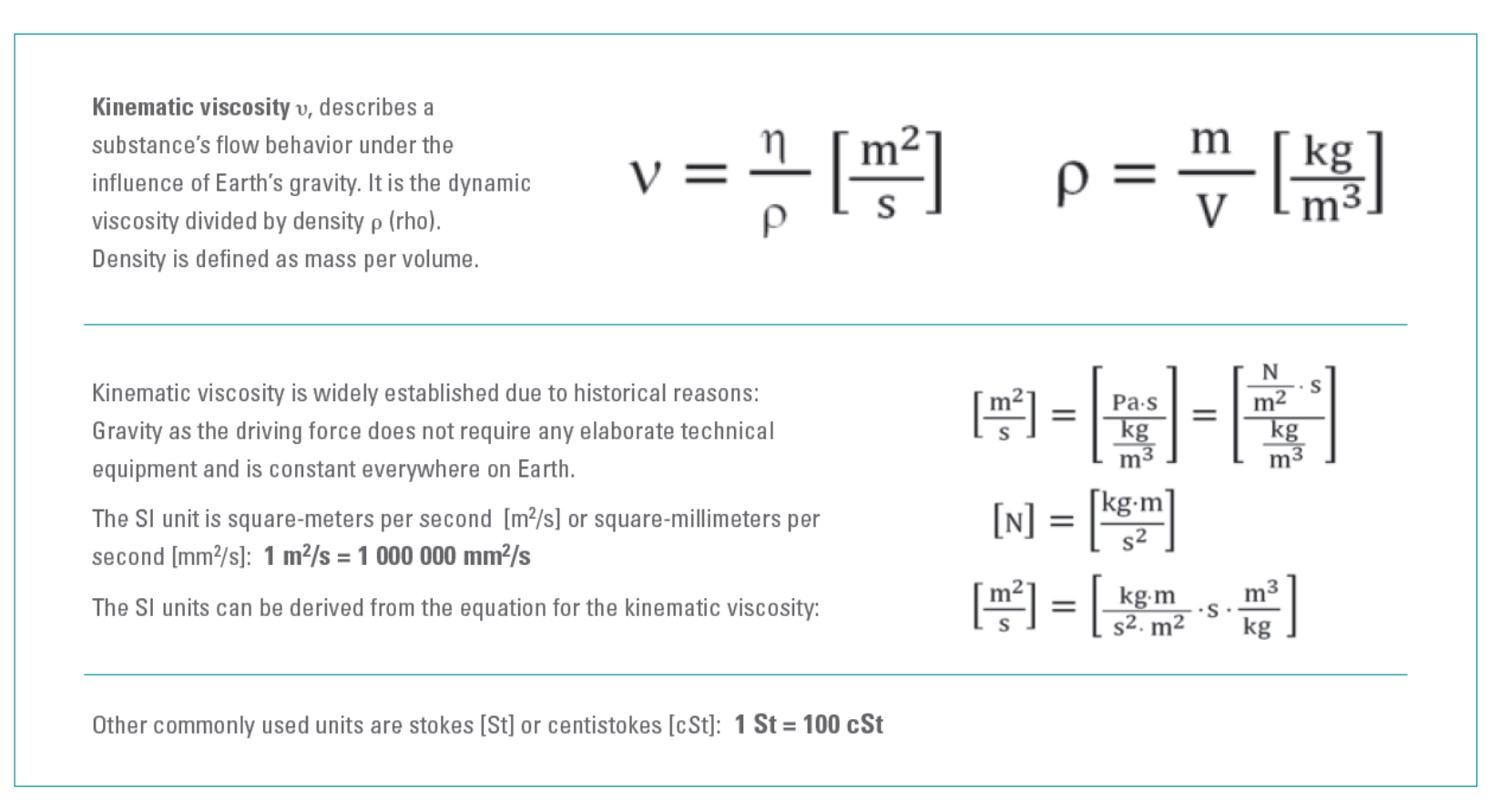

对于设备状态监测,我们通常使用运动粘度来表征油品的粘度,它被定义为在重力作用下油液自身表现出的流动阻力。

油液的粘度受到以下因素影响:

• 温度变化 – 油液的粘温指数(VI)是指油的粘度随温度变化而发生变化的规律。更高的VI值表示油品粘度受温度变化影响相对较小,而较低VI值表示油品粘度受温度变化影响相对较大。在40℃和100℃之间粘度变化较小的油品比粘度变化较大的油品有着更高的VI值(粘度指数)。粘度指数基于测试(ASTMD2270)在40℃(1040°F)和100℃(2120°F)的油品的运动粘度得出,高于95的粘度指数值被认为是较高的。具有高VI的油品可以在宽范围温度下对关键组分提供更好的保护。

• 添加剂 – 添加剂是润滑油配方的一部分。例如,多级矿物基发动机油(除了天然高VI的基础油)用弹性添加剂配制,所述弹性添加剂在低温下收缩并且在高温下膨胀以补偿油液的流动性。

• 热和氧化、老化副产物– 这些副产物是不溶的,但是会以悬浮的形式存在于油中。

• 烟炱 – 常见于柴油发动机,烟炱是一种在油品中形成胶体悬浮的颗粒。润滑油中的分散剂添加剂是用来防止烟炱颗粒聚集和生长,避免胶体悬浮液形成的添加剂。

• 水污染 – 油和游离水不溶,不会发生化学反应,但在某些情况下,它们会结合形成乳状液(乳化),看起来像加奶油的咖啡,这实际上会增加油的运动粘度。

Measuring Kinematic Viscosity

Gravimetric Capillary – The most widely used technique for measuring kinematic viscosity is the use of a Gravimetric Capillary that is temperature controlled, usually 40 C for single grade oils, and both 40 and 100 C for multigrade oils. Measurements using capillary viscometers are based on the relation between viscosity and time. The more viscous an oil, the longer it will take to flow through a capillary under the influence of gravity alone.There are several standardized capillaries in use today. Most laboratory instruments employ glass capillaries, or ‘tubes.’ A more recent advancement for field measure of kinematic viscosity employs a split aluminum cell capillary

The instruments are designed to work as either direct-flow or reverse-flow capillaries. In direct-flow capillaries, the sample reservoir is located below the measuring marks. In reverse-flow types the reservoir sits above the marks. Reverse-flow capillaries allow the testing of opaque liquids and some can have a third measuring mark. Having three measuring marks provides two subsequent flow times and improves the measurement repeatability.

► PORTABLE, SOLVENT FREE DIRECT FLOW CAPILLARY VISCOMETER

Field or mobile applications where a kinematic viscosity result is required can be satisfied with a new generation of viscometers based on the Hele-Shaw split cell capillary design. A single heated aluminum block with a machined capillary enables temperature controlled viscosity at 40 C without use of solvents for cleaning.

As with lab systems, a 60 microlitre sample is pipetted and introduced to a temperature controlled cell, usually set at 40 C. The device reports the kinematic viscosity directly on the screen when complete. After testing, the operator cleans the plates vigorously with a cleaning pad, and the cell is warmed for the next sample.

► MANUAL CONSTANT TEMPERATURE BATH SYSTEMS

These systems consist of a very precise temperature controlled bath, in which the direct flow capillaries are immersed. A sample of oil, usually 10 ml, is suctioned into the tube until it reaches the start point. The suction is then released and the oil flows by gravity through the controlled capillary section of the tube. Two or three marks are visible on the tube. An operator watches the meniscus of the oil as it passes the start point. At this point, the operator times how long it takes the oil to pass the final mark. The tubes are selected such that the test will take a minimum of 200 secs to complete. This makes it easier for manual timekeeping. ASTM D 445 is the method for kinematic viscosity and was originally written for the manual method.

► AUTOMATED MODIFIED UBBELOHDE METHOD

A common system used by labs is an automated modified Ubbelohde method. A 10 ml bottle is placed in a small carousel rack. The system draws oil up to the tubes as per the manual method, though in this case all the tasks are controlled by a computer program. The system does not require an operator to monitor and time the oil flow.

Important Conclusions

Viscosity is a critical fluid property, and viscosity monitoring is essential to oil analysis. Be sure to investigate kinematic viscosity measurement techniques for used oils, and be aware that methods differ slightly. It is important that the details of viscosity measurement are understood, so accurate lubrication decisions can be made.

When looking for an onsite viscometer, don’t look for complete agreement between the laboratory’s kinematic viscometer and the onsite instrument, especially for field systems. Consider the technique, the conditions and user environment. Are solvents difficult to obtain or maintain? Is the equipment being used routinely? Always baseline the new oil with the same viscometer you are using with the in-service oil. Back to oil analysis page.

Get your free e-guide and find out more

Download E-guide